Supply chain performance monitoring: What’s at stake?

Recent tech advances make it possible to track supply chain performance in real time by continuously analyzing data—and logistics leaders are taking notice. As global trade fragments and international supply chains see rising disruption from inflation and climate change, logistics companies need better tools to keep them ahead of potential challenges. Plus, increased operating and insurance costs combined with low freight rates and excess stock concerns have prompted 3PLs to look for new ways to improve efficiency.

That search has led 3PLs to invest in technologies like AI, end-to-end visibility and process automation, all of which are essential to establishing an effective supply chain performance monitoring practice. But because moving toward real-time data analysis might require multiple new tech implementations, it’s important to understand how 3PLs are using their newest solutions to streamline their processes and drive better performance across their entire business.

Here, we’ll talk about some of the key benefits of supply chain performance monitoring and start to weigh how the initial investment could be offset by unmatched benefits for 3PLs.

Advanced operational efficiency

Performance monitoring allows 3PLs to track their operations continuously and create strategies based on data rather than hunches. Without it, leaders are left to reflect on reports rather than react as needs arise.

Supply chain performance monitoring can help identify inefficiencies and optimize routes, leading to cost savings and improved customer satisfaction. On the partner side, providing clients with real-time updates on the status of their shipments is a great way to build transparency and trust.

Easier compliance and reporting

3PLs can have a hard time keeping up with constantly shifting requirements from business partners, leading to problems that must be corrected before trade can return to normal. Performance monitoring practices help 3PLs stay up to date and comply with regulatory requirements, like tracking and tracing for safety standards, and simplify the generation of reports for both audits and compliance checks.

Simplifying a once-challenging element of the supply chain with an automated solution can have other downstream results in terms of bandwidth and time saved. By adjusting to changing requirements as they evolve, 3PLs can cut out the compliance catch-up and turn their attention to other areas of the business.

Streamlined cost management

By continuously monitoring KPIs such as fuel consumption, driver performance, on-time ship metrics and asset utilization, logistics businesses can identify areas where costs could be cut immediately instead of waiting to see the results in a quarterly report.

When margins are thin, real-time da ly ta allows businesses to save money by making decisions at the right time rather than waiting weeks or months down the line—long after the opportunity has passed or the problem has gotten worse.

Enhanced partner collaboration

Supply chain data sharing enhances collaboration between 3PLs and their partners by ensuring all parties have access to the same information at the same time.

This reduces potential misunderstandings and misses on the 3PL’s behalf, which can be costly to the business and the customer relationship.

A stronger competitive edge

3PLs that leverage supply chain performance monitoring can differentiate themselves from competitors by offering more service options, which are especially important in rapidly changing markets. By implementing a robust supply chain performance monitoring practice, 3PLs will find it easier to keep existing and win new contracts.

As the business grows and takes on more clients, real-time performance monitoring can scale with them, with always-on data providing the flexibility needed to manage increasingly complex logistics networks.

As markets shift with customer expectations and international disruptions, supply chain performance monitoring is the key for forward-thinking logistics businesses that are looking to stay ahead of all the changes.

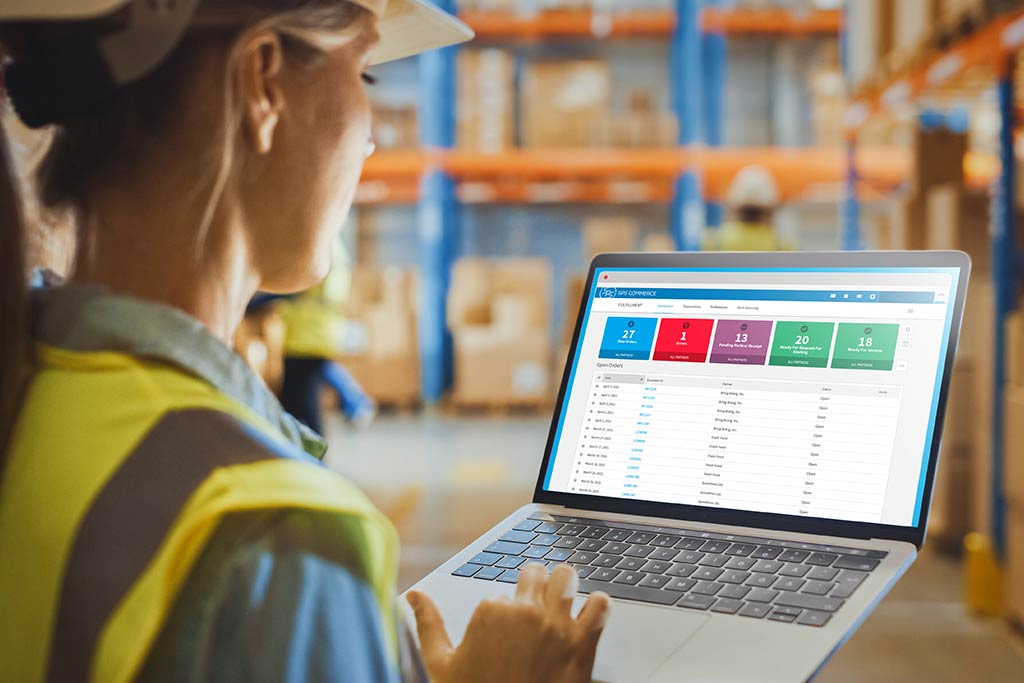

Thinking more about implementing supply chain performance monitoring practices at your company? See how solutions from SPS Commerce can help 3PLs stay in sync.

- Supply chain performance monitoring: What’s at stake? - November 6, 2024

- What is operational flexibility? - October 21, 2024

- The 5 biggest demand forecasting challenges in supply chains – and how to fix them - October 17, 2024

RELATED POSTS

Building brand trust: why transparenc...

What is operational flexibility?

The 5 biggest demand forecasting chal...