The EDI 862 format

The EDI 862 format is designed to convey detailed and dynamic shipping instructions from the buyer to the supplier, enabling efficient and timely order fulfillment.

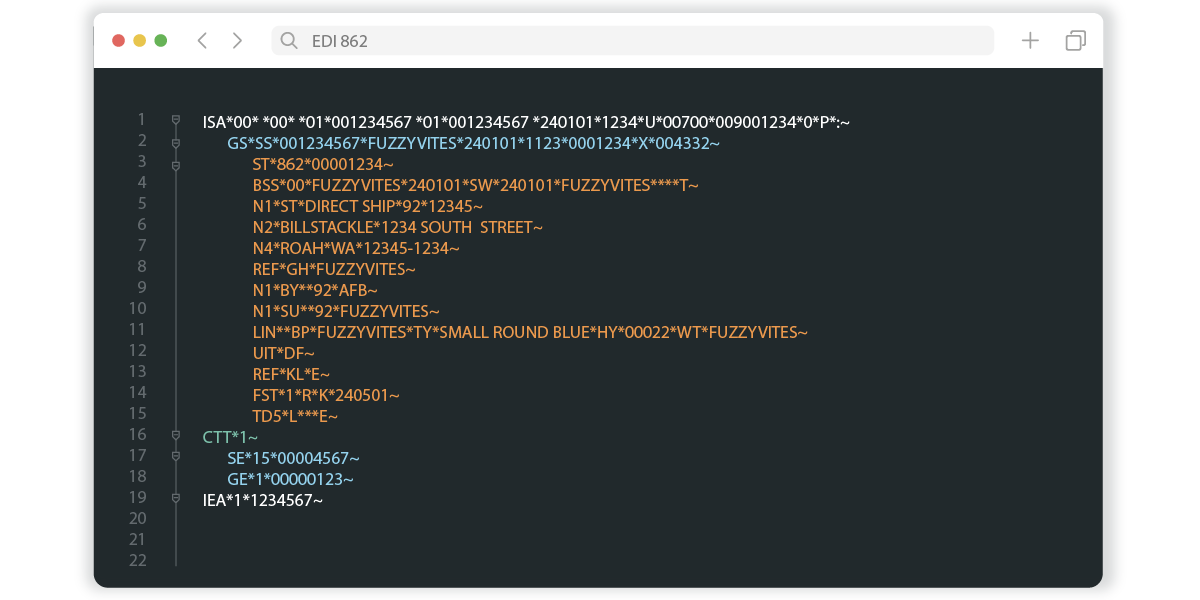

A typical EDI 862 document might include several key segments:

BSS: Beginning segment for shipping schedule

DTM: Date/time reference

N1: Name

LIN: Item identification

SCH: Line item schedule

TD5: Carrier details

REF: Reference information

How is the EDI 862 used?

Detailed shipping instructions:

Just-in-time (JIT) manufacturing support:

Order adjustment:

Integration with production planning:

Benefits of using an EDI 862 Shipping Schedule

Increased Efficiency:

Automates transmission of shipping schedules, reducing manual processes and minimizing errors and delays.

Improved Responsiveness:

Enables rapid adjustments to shipping schedules, helping businesses adapt quickly to changing demand needs.

Reduced Inventory Costs:

Supports effective JIT inventory strategies, lowering inventory carrying costs by reducing the need for large stock holdings.

Enhanced Collaboration:

Facilitates clear, timely communication between buyers and suppliers, fostering better collaboration with up-to-date shipping information.

Better Customer Satisfaction:

Leads to more reliable order fulfillment, significantly enhancing customer satisfaction and loyalty.

Common issues regarding EDI 862

Data Accuracy and Timeliness:

Inaccuracies or delays in EDI 862 data transmission can disrupt JIT manufacturing schedules, leading to production delays, excess inventory, or stock shortages.

Integration Challenges:

Properly integrating EDI 862 data into both supplier and buyer systems can be complex, and misalignment can lead to inefficiencies.

Compliance and Scalability:

Ensuring compliance with diverse trading partner specifications and scaling EDI systems to handle increased transaction volumes without compromising performance can be resource-intensive.

Resource and Security Requirements:

Managing EDI 862 transactions demands specific expertise and robust security measures to protect sensitive business information from data breaches.

Automate EDI 862 Shipping Schedule with Full-Service EDI from SPS Commerce

Managing ongoing EDI tasks can be complex and time-consuming. Full-service EDI providers like SPS Commerce deliver EDI technology and associated staffing resources responsible for customizing, optimizing and operating your EDI solution.

A full-service provider, like SPS Commerce, has an expert team that handles ongoing management of your EDI solution. The SPS team actively manages 9,000 changes from retailers each year.

SPS communicates directly with your trading partners to manage connectivity, setup, requirements, updates and support efforts. SPS also takes ownership of understanding your trading partner requirements and making map changes.

SPS Fulfillment proactively monitors and optimizes your solution to prevent errors and minimize data entry.

Interested in learning more about our EDI solution?

Additional EDI Resources

Enter a virtual library of information about EDI for suppliers, vendors and distributors to provide you with the product knowledge you need to power your business.

Ultimate List of EDI Transactions

Here are some of the most common documents and transactions that are supported through EDI automation.

Five Top EDI Documents to Automate

When you automate your most-used EDI documents, it can significantly cut down keystrokes and speed up processes.

EDI Glossary

Terminology including retail definitions, order management models, supply chain roles, software and distribution channels.

EDI for Suppliers & Vendors

Discover how leading vendor and supplier businesses are serving their customers better with EDI solutions from SPS Commerce.