What is inventory planning?

- What is inventory planning?

- Why is inventory planning important?

- The benefits of inventory planning

- What are the challenges of inventory planning?

- How to develop an inventory plan

- When should inventory planning take place?

- What is the difference between inventory planning and assortment planning?

- What makes inventory planning essential to eCommerce?

- Frequently Asked Questions (FAQs)

- Inventory planning powered by SPS Commerce

“[A benefit from SPS has been] watching inventory levels so we can react by adjusting an order.”

– Apparel customer, G2 Crowd

What is inventory planning?

Inventory planning – also known as stock planning – involves all the data and strategies used by retailers and suppliers to manage the items they carry, store and sell.

An effective stock planning strategy taps into data from historic and real-time sales, customer feedback and seasonal trends to make sure retailers and suppliers are equipped with inventory to meet demand while avoiding waste and warehouse delays.

The benefits of inventory planning include increased sales, improved cash flow and an enhanced customer experience.

Why is inventory planning important?

Inaccurately estimating inventory causes issues like over- and under-stocking, warehouse bottlenecks and delays. With informed inventory planning, businesses can avoid these types of issues and respond faster to sales trends.

Savvy retailers and suppliers use data to understand trends and buying habits, then plan accordingly to increase sales and limit dead stock.

The benefits of inventory planning

Some of the common benefits of inventory planning include:

- Increased sales – understand trends and buying habits to meet demand with enough stock during peak periods

- Reduced waste – gain insight into historic, real-time and seasonal demand to avoid over-stocking

- Boosted cash flow – access accurate inventory demand data to reduce capital tied up in stock

- Reduced delays and time to market – improve warehouse layout and access with streamlined inventory

- Improved customer experience – get the right amount of stock when needed to eliminate delays, bottlenecks and overselling (selling stock the businesses don’t have)

- Improved forward planning – limit the impact of unexpected challenges such as delivery delays

What are the challenges of inventory planning?

Inventory planning has the power to make or break businesses, and it’s more complicated than just analyzing trends and buying popular products.

Efficient and effective stock planning requires many processes and participants to be aligned: a comprehensive analytics platform to automate data-gathering and present insights; informed sales and marketing teams that understand consumer habits; and optimized supply chains that keep inventory moving smoothly through the sales process.

Some of the key challenges in inventory planning include:

- Data gathering – Data is collected from a range of sources, including real-time and historic data, and customer feedback. Ideally, this process needs to be automated in a single platform to inform inventory decisions.

- How to manage new products – This is more complicated without sales data. Businesses must be agile to tap into real-time insights in-season and adjust inventory management strategies accordingly.

- Stockouts and over-stocking – Even armed with comprehensive data, inventory planning isn’t an exact science. Retailers and suppliers must be able to respond in real time to avoid a poor customer experience or waste from dead stock.

- Disorganized data – The process of gathering, formatting and organizing data from a range of sources in a single, uniform database is challenging. This process needs to be automated to save time and costs.

- Lack of visibility into partners – Every participant in the supply chain must work together to make sure stock is not only ordered, but delivered on time without bottlenecks. A comprehensive EDI system provides the visibility needed to adapt swiftly to challenges.

- Picking processes – Inventory planning doesn’t end with ordering. Warehouse layout and picking processes are also key to minimizing delays and time-to-market.

How to develop an inventory plan

Sales inventory process planning involves collaboration between various tools, teams and processes.

Only by identifying the data and insights needed to drive efficient inventory – and the people power to bring these insights to life – can businesses reap the rewards.

Some of the key stages in developing an inventory plan include:

- Data collection – This includes historic and real-time sales data, customer intent data such as Google Trends and sales and marketing data such as customer feedback. By aligning insights in a single platform, businesses can confidently make informed decisions and access the visual overviews needed to remain agile and react quickly.

- Data review – Suppliers and retailers should implement regular reviews to analyze the latest insights, compare against historical trends and make adjustments to ongoing inventory trends.

- Turn insights into tactics – With added visibility, suppliers and retailers can roll out markdowns or promotions based on real-time data to maximize sales and avoid waste.

- Identify inventory planning models – Businesses should roll out an appropriate inventory model based on sales performance and the business model. Possible models may include:

- Economic Order Quantity (EOQ) – a model designed to identify the optimal order quantity to meet demand without overstocking

- Perpetual inventory – a digital system used to record real-time inventory as it enters and leaves the warehouse, designed to provide real-time data and minimize manual stock-taking

- Periodic inventory – physical stock-taking at regular intervals, for example, monthly

- Just in Time (JIT) – inventory is only ordered when needed, to reduce holding costs

- Lean inventory – continuous review of the inventory plan to remove any wasteful elements at the earliest opportunity

- Vendor Managed Inventory – a model that sees the manufacturer or supplier assume responsibility for the retailer’s inventory decisions, using their insights on materials and allowing the retailer to spend more time on activities such as marketing

- Set KPIs – These defining metrics help businesses review performance. They include all the measures relevant to the business, such as turnover, profit, customer satisfaction, data system accuracy, picking and delivery times, warehouse capacity and more. The insight gathered from KPIs can be used to quickly identify successes and failures so that businesses can streamline their inventory plan.

When should inventory planning take place?

Stock planning isn’t a one-time or annual activity – to gain the most benefit, it must be ongoing.

However, the data that supply chain businesses analyze to support their inventory planning decisions may change slightly depending on their current phase or time of year. These include:

- Pre-season – In the build-up to key trading periods, businesses may use historic seasonal sales data to inform their purchasing decisions and capitalize on demand.

- In-season – During key trading periods, retailers may tap into real-time sales data and adjust inventory decisions accordingly to avoid waste from overstocking and address any bottlenecks or delays.

- Post-season – After each key trading period, businesses should review performance data and highlight key challenges to avoid or successes to recreate in the future.

What is the difference between inventory planning and assortment planning?

Assortment planning comes first. This involves picking the product clusters and SKUs that must be available in different regions to meet demand. For example, red t-shirt sales might be high-performing in one state but blue sweatshirts are more popular in another.

This leads us to inventory planning – building on this data to decide exactly how much inventory is needed, where and when. This involves specific stock decisions that maximize sales and avoid waste and bottlenecks in fulfillment.

Inventory planning and assortment planning both require that the right products are available to manufacturers and retailers at any given time to fulfill demand. The two processes need to work together for optimal success.

What makes inventory planning essential to eCommerce?

Inventory planning is key to any manufacturer, supplier and retailer. However, it is arguably nowhere more important than in eCommerce, where it can make or break an online business.

Consumer research suggests shoppers are less likely to show brand loyalty online, and they will prioritize price and convenience over returning to their favorite eCommerce store.

Inventory planning is key for online retailers to meet the demand for affordable products and a quick, simple shopping experience. An eCommerce seller should:

- Keep prices affordable – Businesses pass the benefits (in cost savings and increased turnover) of accurate inventory planning onto the customer.

- Avoid out-of-stocks – This is caused by under-stocking, which sees modern online consumers swiftly leave for a competitor.

- Speed up delivery times – Keep the right amount of stock available and accessible in warehouses. This is especially important for those offering next-day delivery services.

- Prevent overselling – Present the latest, accurate inventory data in an intuitive data platform. This avoids a poor customer experience through unfulfilled orders.

Frequently Asked Questions (FAQs)

What is the goal of inventory planning?

What are the four types of inventory?

What is an inventory planning model?

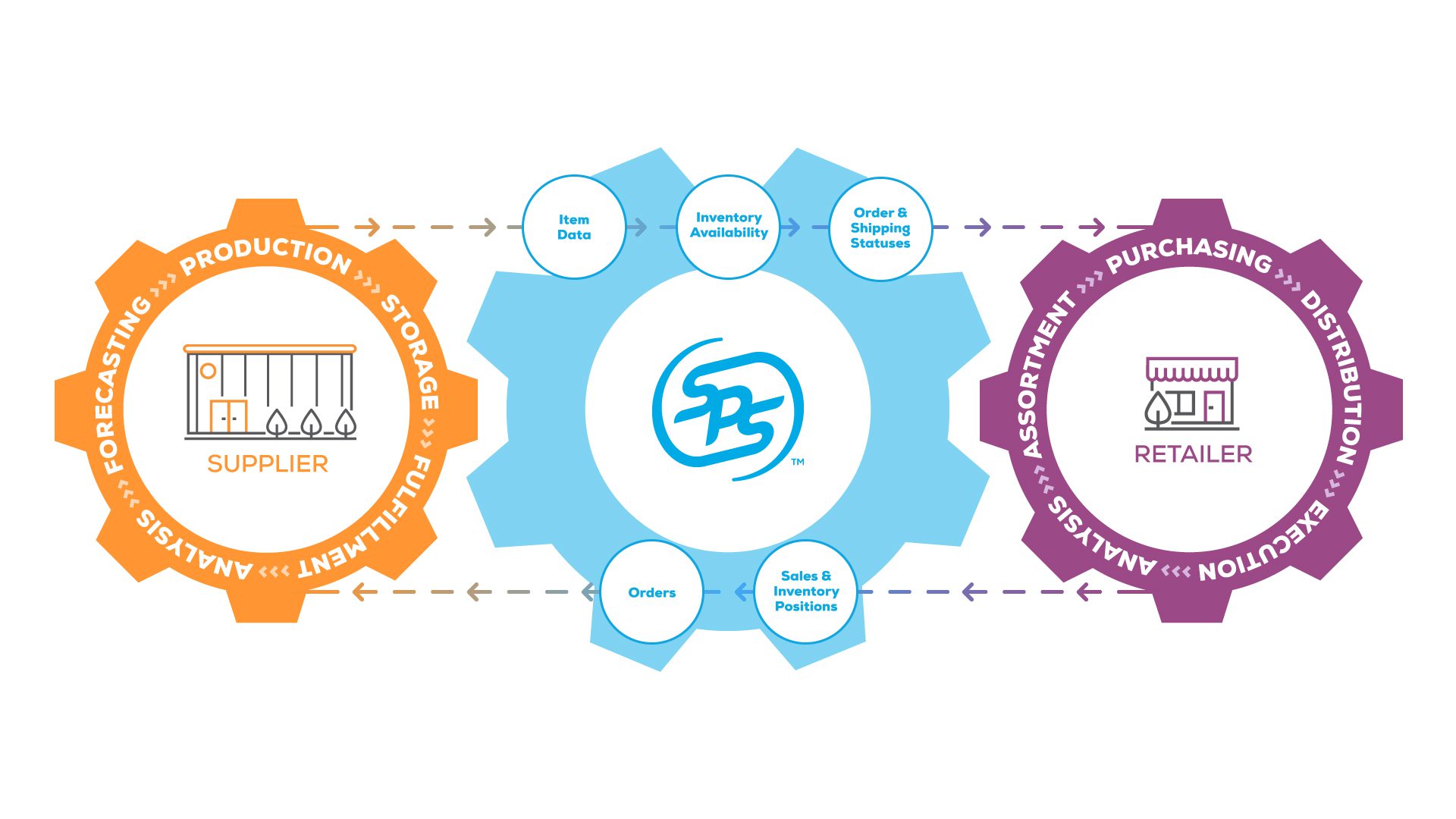

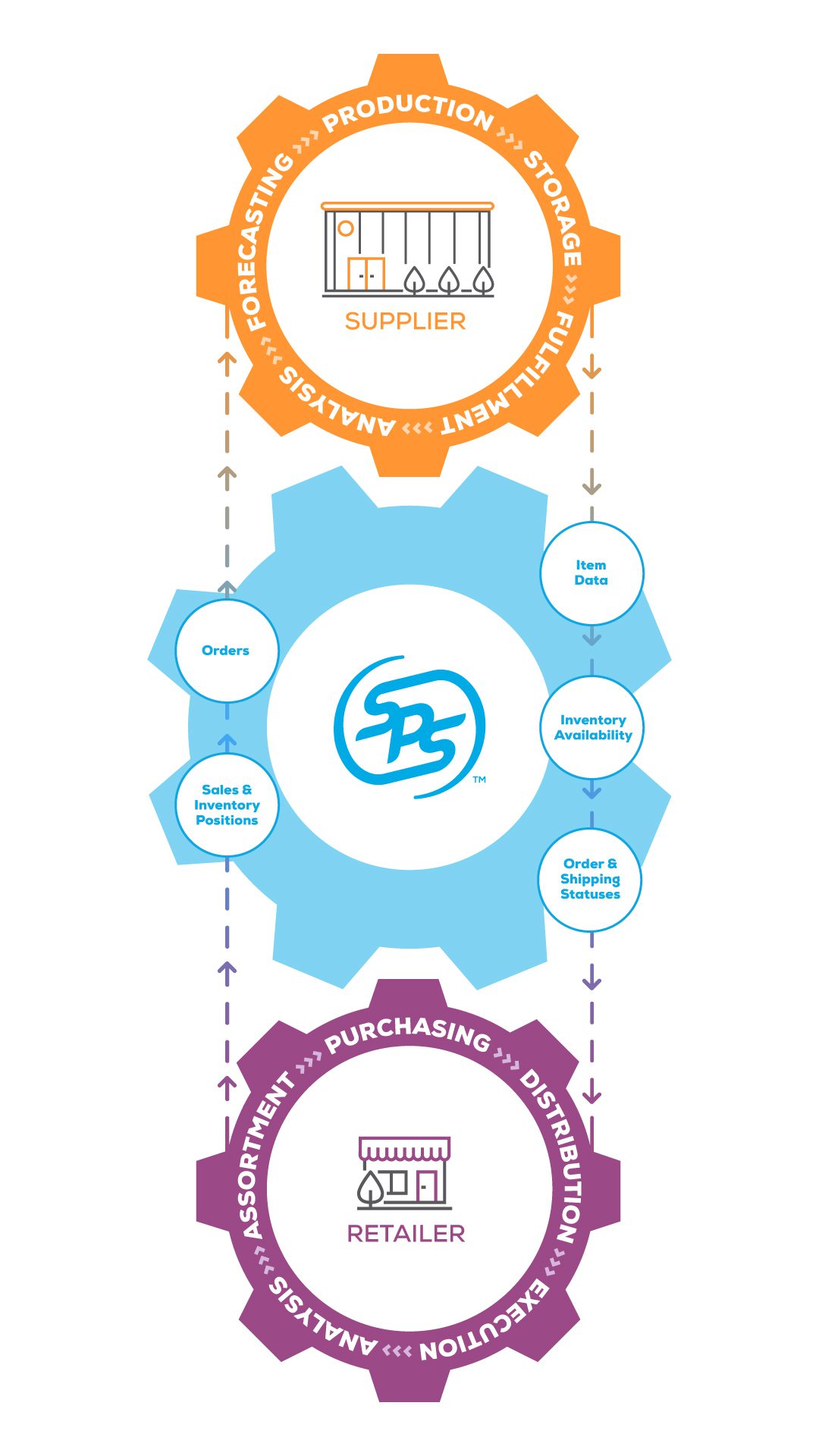

Inventory planning powered by SPS Commerce

Interested in turning your sales and community data into powerful insights that transform your inventory planning? Inventory management services from SPS Commerce give you visibility over inventory from supplier to consumer. Information-sharing becomes easier with our standardized analytics dashboards, empowering stronger collaboration with your trading partners. Let us help ensure you always have goods in the right place at the right time.